In the broad area of materials scientific research, round graphite, as a kind of high-performance carbon material, is progressively ending up being the focus of lots of high-tech areas with its special architectural features and large application potential customers. Unlike typical flake or powdered graphite, round graphite, with its virtually perfect spherical form and high formation, exhibits exceptional electric conductivity, high-temperature resistance, and mechanical stability, which make it play an important function in lithium-ion batteries, conductive composite products, chemical catalysts, and numerous various other modern items.

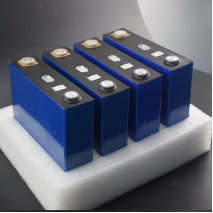

In the area of lithium-ion battery manufacturing, spherical graphite is the front runner for the production of unfavorable electrode materials. Its little particle dimension and high pureness not just improve the power density and cycle life of the battery however likewise optimize the machining performance of the electrode material so that the battery can work much more stably in the quick cost and discharge procedure. With the remarkable increase, the demand for high-performance spherical graphite has likewise climbed, driving technological development and capacity growth in this field.

(Spherical graphite is used in the manufacture of lithium-ion batteries)

In conductive plastics, rubber finishes, and various other composite products, round graphite is commonly utilized as a reinforcing material, which can effectively enhance the electric conductivity and electro-magnetic protecting efficiency of items while preserving good physical and mechanical residential or commercial properties. Particularly in the aerospace, digital packaging, and antistatic areas, this light-weight and highly effective conductive filler is essential to minimize weight and enhance safety and security and capability.

(Spherical graphite used in conductive plastic composites)

Due to its excellent certain surface area and security, round graphite is additionally taken into consideration a perfect product for sophisticated stimulant service providers. In the chemical reaction procedure, it can offer adequate energetic websites to advertise reliable contact of reactants, thereby enhancing catalytic effectiveness and product selectivity. Particularly in the synthesis of fine chemicals and environmental therapy technology, spherical graphite-based catalysts have shown fantastic potential.

Looking to the future, with the expanding worldwide need for lasting power solutions and high-performance products, the r & d of spherical graphite will remain to heat up. Technical advancement, such as better manufacturing processes, stricter quality control and the growth of brand-new composite materials, will certainly be the crucial elements driving the advancement of this industry. On top of that, the expedition of eco-friendly production technologies and recycling programs is additionally an essential direction to make certain the lasting growth of the round graphite industry.

However, despite basic material rate fluctuations, high production energy intake, and environmental pollution, the market has to continue to look for innovations via technical development to reduce manufacturing prices, improve source use, and reduce the ecological impact of the manufacturing procedure. At the same time, strengthening global teamwork, sharing research and development results, and jointly handling worldwide challenges will certainly be the only means to advertise the healthy development of the round graphite market.

Simply put, round graphite is just one of the key products in the 21st century, and its vast application and possible value in the field of brand-new energy and new products can not be underestimated. With the progress of science and technology and the continuous updating of market need, this area will introduce a more great development prospect.

Vendor

Graphite-crop corporate HQ, founded on October 17, 2008, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of lithium ion battery anode materials. After more than 10 years of development, the company has gradually developed into a diversified product structure with natural graphite, artificial graphite, composite graphite, intermediate phase and other negative materials (silicon carbon materials, etc.). The products are widely used in high-end lithium ion digital, power and energy storage batteries.If you are looking for graphite to graphene, click on the needed products and send us an inquiry: sales@graphite-corp.com

Inquiry us