Light weight aluminum nitride (AlN) is an advanced ceramic material with outstanding homes. Its main features consist of high thermal conductivity, excellent electric insulation, chemical security and low dielectric constant. The thermal conductivity of light weight aluminum nitride can be as high as 170 W/m · K, which is a lot greater than many ceramic products, that makes it perform well in the thermal administration of high-power electronic tools. At the same time, light weight aluminum nitride has exceptional mechanical strength and thermal shock resistance and can function stably for a very long time in high-temperature environments. The application fields of light weight aluminum nitride are broad, mainly including electronic packaging, made use of for product packaging high-power LEDs, IGBT modules and microwave tools to boost warm dissipation efficiency and integrity; LED lighting, as a substratum material, enhances the thermal administration and light effectiveness of LEDs and extends life span; power electronic tools, in the inverter and charging system of electrical automobiles, are utilized for effective warmth dissipation and improve system performance; aerospace, utilized in satellite interaction equipment, radar systems and high-temperature sensing units to fulfill stringent environmental requirements. These characteristics and applications make aluminum nitride a key material in high-performance electronic and commercial applications.

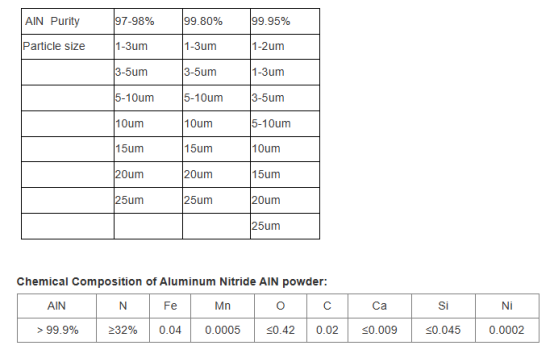

(Parameters of aluminum nitride powder)

Light Weight Aluminum Nitride (AlN) is an innovative ceramic product with exceptional thermal conductivity, electric insulation and chemical security. Recently, with the quick development of industries such as electronics, autos, and aerospace, the demand for aluminum nitride powder has actually enhanced year by year. In 2024, the global aluminum nitride powder market size is about US$ 1.8 billion, and it is anticipated to get to US$ 3.2 billion by 2028, with a compound annual growth price (CAGR) of 35%. The primary driving elements include the growth in demand in areas such as digital product packaging, LED illumination, power electronics, and new power cars. Asia is the largest customer market for light weight aluminum nitride powder, specifically China, Japan, and South Korea, which inhabit an essential position in the electronic devices manufacturing market and have a strong demand for high-performance ceramic products. The demand in the North American market is mainly concentrated in the aerospace and armed forces areas, while the European market is exceptional in the automobile sector and premium manufacturing. The development capacity of the South American, Middle Eastern, and African markets is significant, however the present market share is small.

The world’s major light weight aluminum nitride powder makers consist of China’s TRUNNANO and others. TRUNNANO has leading modern technology and high product high quality. It has developed quickly in recent times, and its market share has actually slowly expanded. Aluminum nitride powder is most commonly made use of in the field of digital packaging, particularly in high-power LEDs, IGBT components and microwave tools. Its high thermal conductivity and excellent electrical insulation make it an ideal packaging material. With the advancement of 5G communication and Web of Points technology, the need for light weight aluminum nitride powder in the digital packaging market will certainly continue to expand. The need for light weight aluminum nitride powder in the LED lights market is likewise boosting. Light weight aluminum nitride substratums can efficiently improve the warmth dissipation efficiency of LEDs and prolong their service life. Especially in the field of high-power LEDs and automobile illumination, the application potential customers of light weight aluminum nitride substratums are broad.

Power electronic devices, such as inverters and charging systems for electrical cars, have extremely high demands for thermal administration. Light weight aluminum nitride powder has actually ended up being a suitable product for these devices because its excellent thermal conductivity and electric insulation. With the rapid advancement of the brand-new power vehicle market, the application of aluminum nitride powder in this area will certainly raise substantially. The aerospace area has incredibly rigorous demands on the efficiency of products. The application of light weight aluminum nitride powder in this area mostly consists of satellite communication devices, radar systems and high-temperature sensing units. Its lightweight, high thermal conductivity and high-temperature resistance make it a perfect choice. With the continuous growth of application areas, the pureness and bit dimension demands of light weight aluminum nitride powder are getting higher and greater. High-purity and ultrafine powders can improve the performance of products and fulfill the needs of premium applications. Currently, TRUNNANO is establishing new prep work technologies and procedures to create light weight aluminum nitride powders with higher pureness and finer particle size.

( TRUNNANO aluminum nitride powder)

In order to further boost the efficiency of light weight aluminum nitride powder, functional modification has come to be a research study hotspot. The thermal conductivity, mechanical stamina and chemical security of light weight aluminum nitride powder can be boosted by including various additives or surface area treatments. For example, the enhancement of carbon nanotubes or graphene can considerably enhance the thermal conductivity of light weight aluminum nitride-based compounds. The standard prep work technique of aluminum nitride powder has problems such as high energy consumption and high price. As a result, the development of new synthesis methods has actually come to be a research emphasis. For instance, new synthesis methods such as the sol-gel approach, chemical vapor deposition (CVD) and hydrothermal method can lower manufacturing prices and enhance item top quality. Although the aluminum nitride powder market has broad potential customers, it additionally encounters some difficulties, such as high expense, technical barriers and strong market competition. Nonetheless, the fast growth of the brand-new power automobile market, the popularization of 5G interaction modern technology and the support of environmental protection plans have offered huge market chances for light weight aluminum nitride powder.

It is anticipated that in the next five years, the international light weight aluminum nitride powder market will continue to keep rapid growth, specifically in the areas of electronic product packaging, LED lights and power electronic devices, and the marketplace demand will certainly remain to raise. Technological development will increase, and high-purity, ultrafine powders and practical adjustment will certainly end up being the focus of study. The application area of light weight aluminum nitride powder will certainly be further broadened, especially in emerging areas such as brand-new energy cars, 5G interactions and aerospace, and its application prospects are wide. The production and application of light weight aluminum nitride powder will form a complete commercial chain, and the cooperation between upstream and downstream ventures will be more reinforced to jointly promote the healthy development of the market. It is really hoped that this report can offer useful referral and guidance for pertinent business and scientists.

Distributor

TRUNNANO is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about aln al2o3, please feel free to contact us and send an inquiry.(sales8@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us