Spherical Tungsten Powder: A Revolutionary Product for Advanced Applications

Advancing Modern Technology and Industrial Advancement with Spherical Tungsten Powder

(Spherical Tungsten Powder)

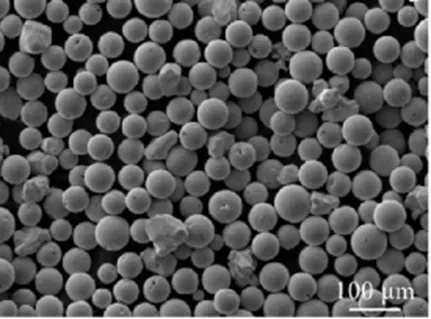

In the quickly progressing landscape of products scientific research, round tungsten powder stands out as a principal in driving innovations across several industries. This distinct material is identified by its completely round fragments, which use distinct benefits over traditional irregularly shaped tungsten powders. The production of spherical tungsten powder entails innovative manufacturing procedures, including plasma spheroidization or gas atomization methods that guarantee consistent particle shapes and size. These attributes not just enhance the product’s flowability and packaging density however additionally considerably enhance its performance in different applications.

The superior residential or commercial properties of round tungsten powder make it indispensable in high-technology fields such as aerospace, automotive, electronic devices, and clinical tools. In aerospace design, the product’s high melting factor, outstanding thermal conductivity, and resistance to severe temperatures and stress make it suitable for usage in rocket nozzles, combustion chambers, and heat shields. Likewise, in the auto industry, this powder adds to the development of more resilient and efficient elements like exhaust shutoffs and turbochargers. For digital suppliers, round tungsten powder works as a crucial basic material for generating conductive pastes utilized in thick film circuits and semiconductor product packaging. Furthermore, within the medical field, it helps with the development of radiation shielding tools and accuracy surgical tools. As study into new usages continues, the potential applications for round tungsten powder are broadening, assuring also better technologies in the future.

Environmental Sustainability and Financial Benefits of Round Tungsten Powder

The fostering of spherical tungsten powder not just thrusts technological progress however also addresses essential ecological and economic obstacles. From an environmental viewpoint, making use of this product can cause minimized waste generation and improved resource efficiency. Typical production methods often result in substantial product loss due to bad powder flowability and irregular particle forms. Nonetheless, the uniformity of spherical tungsten powder allows for better usage during processing, minimizing scrap rates and reducing total manufacturing expenses. Furthermore, its enhanced thermal management abilities add to energy savings by enabling more efficient operation of industrial equipment and machinery.

(Spherical Tungsten Powder)

Economically, the advantages of round tungsten powder are just as engaging. Its capacity to boost item toughness and performance converts into extended service life and minimized maintenance needs, using long-lasting price financial savings for companies. Furthermore, the product’s flexibility supports diversity in product, opening brand-new market possibilities and fostering technology. Manufacturers that integrate round tungsten powder right into their manufacturing processes obtain a competitive edge through improved quality and dependability of their offerings. On a more comprehensive range, the expanding need for this innovative product promotes financial investment in research and development, developing jobs and enhancing financial development. By embracing lasting methods and buying ingenious services, business can satisfy customer assumptions while adding favorably to ecological preservation and financial stability.

Cutting-edge Research and Development in Spherical Tungsten Powder

The ongoing expedition and development of spherical tungsten powder represent a vibrant location of scientific inquiry, driven by the search of enhanced material buildings and unique capabilities. Scientists are continuously pressing the borders of what is possible with this flexible substance, checking out ways to customize its features to satisfy specific application demands. One exciting opportunity of study concentrates on optimizing the synthesis process to accomplish finer control over bit size circulation and morphology. By controling these parameters, researchers aim to unlock extraordinary levels of performance, such as higher strength-to-weight proportions and remarkable electric conductivity. One more location of passion depends on the functionalization of spherical tungsten powder surface areas, where finishings or dopants can be put on introduce added residential or commercial properties like antimicrobial task or catalytic behavior.

Partnerships in between academia, industry, and federal government organizations play a vital function beforehand understanding regarding round tungsten powder. Joint jobs facilitate the exchange of ideas and sources, accelerating the speed of discovery and commercialization. For example, collaborations with universities allow accessibility to cutting-edge facilities and knowledge, while cooperations with private enterprises ensure that technologies have practical applications and market feasibility. Public funding and policy sustain further strengthen these efforts by supplying economic motivations and regulative frameworks that motivate liable development. Through interdisciplinary participation and shared dedication, the worldwide neighborhood can harness the complete capacity of round tungsten powder to deal with complicated obstacles and lead the way for a brighter future. The cumulative effect of these ventures extends beyond individual developments, fostering a society of technology that inspires constant improvement and forward-thinking strategies.

(Spherical Tungsten Powder)

Future Prospects and International Influence of Round Tungsten Powder

Looking ahead, the prospects for spherical tungsten powder appear extremely appealing, with far-ranging implications for worldwide markets and culture at big. As arising technologies remain to develop, the need for products with the ability of conference rigorous performance criteria will only intensify. Spherical tungsten powder is well-positioned to please these demands, using exceptional high qualities that line up with the needs of next-generation applications. In the realm of additive production, also known as 3D printing, this material promises to revolutionize manufacturing processes by enabling the construction of complex parts with premium mechanical homes. Its suitability for this function originates from the excellent flowability and consistency of spherical fragments, making certain trustworthy layer-by-layer construction without jeopardizing structural stability.

Beyond its technological benefits, round tungsten powder holds the prospective to drive social and ecological adjustment on a global scale. By helping with the advancement of cleaner and extra effective modern technologies, it can add to lowering carbon emissions and mitigating climate adjustment effects. Moreover, the product’s involvement in renewable resource systems, such as wind turbines and photovoltaic panels, underscores its duty in advertising sustainable energy options. The health care market stands to profit greatly from advancements in clinical tools and therapies enabled by round tungsten powder. Enhanced imaging technologies and targeted therapies could cause enhanced client results and quality of life. Inevitably, the extensive adoption of this cutting-edge product advertises a brand-new age of progression, where innovation and sustainability converge to develop long-term worth for all stakeholders involved.

TRUNNANO is a supplier of Spherical Tungsten Powder with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about Spherical Tungsten Powder, please feel free to contact us and send an inquiry(sales5@nanotrun.com).

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us